C&A

Warehouse marking at C&A distribution centre

C&A, the fashion brand with a global presence, recently opened their brand-new distribution centre, located near Trnava, Slovakia. Thanks to its strategic location in the Central Eur ope, it will supply their branches located throughout the Central and Eastern Eur ope, in nine countries – Austria, Croatia, Czech Republic, Hungary , Poland, Romania , Serbia, Slovakia and Slovenia.

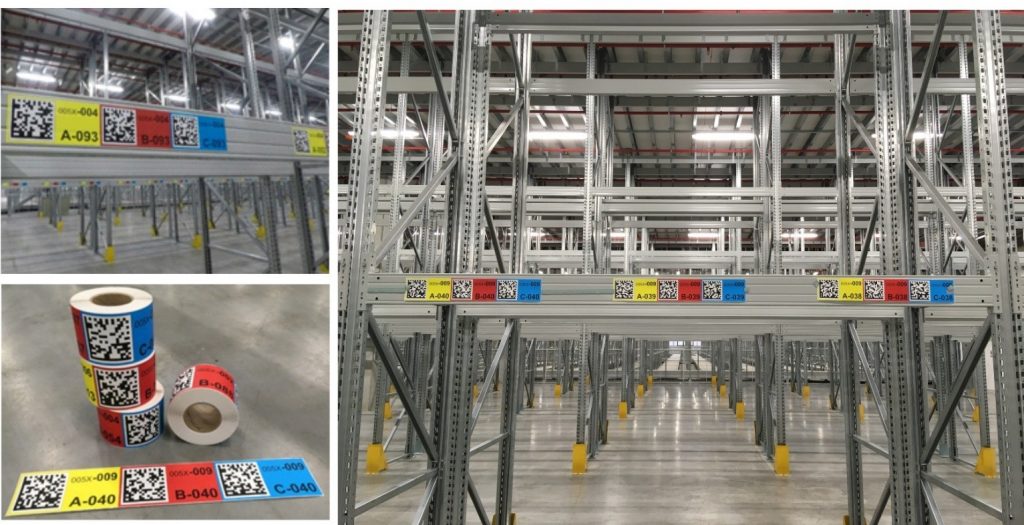

Designing the architecture and planning the structure of a warehouse area in a distribution centre are very important and key factors while implementing new technologies. One of the key factors during the warehouse area planning is, that the warehouse positions are precisely and professionally marked

The area of the C&A distribution centre is 30 000 square metres and it consist of multiple warehouse zones.

Customer’s request was to propose appropriate methods of marking, that will simplify, optimise and streamline the work and orientation within the whole distribution centre.

It was required to mark:

Clothing storage positions

Pallet positions situated on the free ground area

Pallet positions placed on racks

Item positions on shelves

Item positions for the conveyor buffers

In all the cases above , we used labels made from high quality and resistant materials, including the unique Datamatrix code. More than 49 000 positions have been marked.

This ensured the long-term resistance of the marking as well as very easy and precise scanning of the position labels .

Peter KIS Warehouse Operational ManagerWe can consider our new distribution

centre as our flag ship.

During the planning and the construction

phase, we cooperated with the experts only.

For the warehouse marking and installation

was our choice company KODYS SLOVENSKO,

as they have really long-term experience with

warehouses and since the beginning of

this cooperation, every single phase of the project

and all of our requirements were fully understood.

Complete installation was done precisely

and professionally in a very short time

Clothing storage positions

Requirement

- Clothes stored on the hangers

- Marking using plastic label holders

- More than 34 000 positions marked

Solution

- Production of the plastic hangers from special “PPH Scolefin” material that contains 20% of the fiberglass to prevent deformation and ensure stability in various conditions

- Installation took 5 days

Pallet positions situated on the free ground area

Requirement

- Free ground lying pallet positions

- Ceiling height 4 metres, maximum height was 12 metres

- More than 3 500 positions marked

Solution

- Special hanging rail system for easy mounting, without the need to drill into the ceiling

- Easy to adjust positions whenever needed

- More than 1,8 kilometres of rail system was installed

- Installation took 8 days

Pallet positions placed on racks

Requirement

- Three-level pallet racks

- More than 4 200 positions

Solution

- Special color-coded multilevel labels for easy orientation

- All positions can be scanned from the ground

- Installation took 1 day

Item positions on shelves

Requirement

- Positions had to be variable for ability to move them as needed

- More than 7 000 positions

Solution

- Special durable labels with magnetic surface for easy and fast manipulation

- Installation took 1 day

Item positions for the conveyor buffers

Requirement

- Marking of buffers for automatic conveyor line

- More than 500 positions

Solution

- Special PVC KomaTEX signs with 5 mm thickness,

- Installation took 1 day